Acetal Homopolymer vs. Copolymer - What's the Difference?

Learn what makes Acetal Homopolymer different than Acetal Copolymer.

Not all Acetal is created equally!

Acetal is a thermoplastic polymer with the chemical name, 'Polyoxymethylene'. There are two general types of Acetal resins available: Acetal Homopolymer (POM-H), and Acetal Copolymer (POM-C). Acetal Homopolymer resins are currently made by DuPont under the brand name Delrin.

Homopolymer and Copolymer Acetals are very similar in properties and performance. They both have excellent machinability, high strength, stiffness, wear resistance, and dimensional stability. Additionally, both offer FDA and USDA compliance.

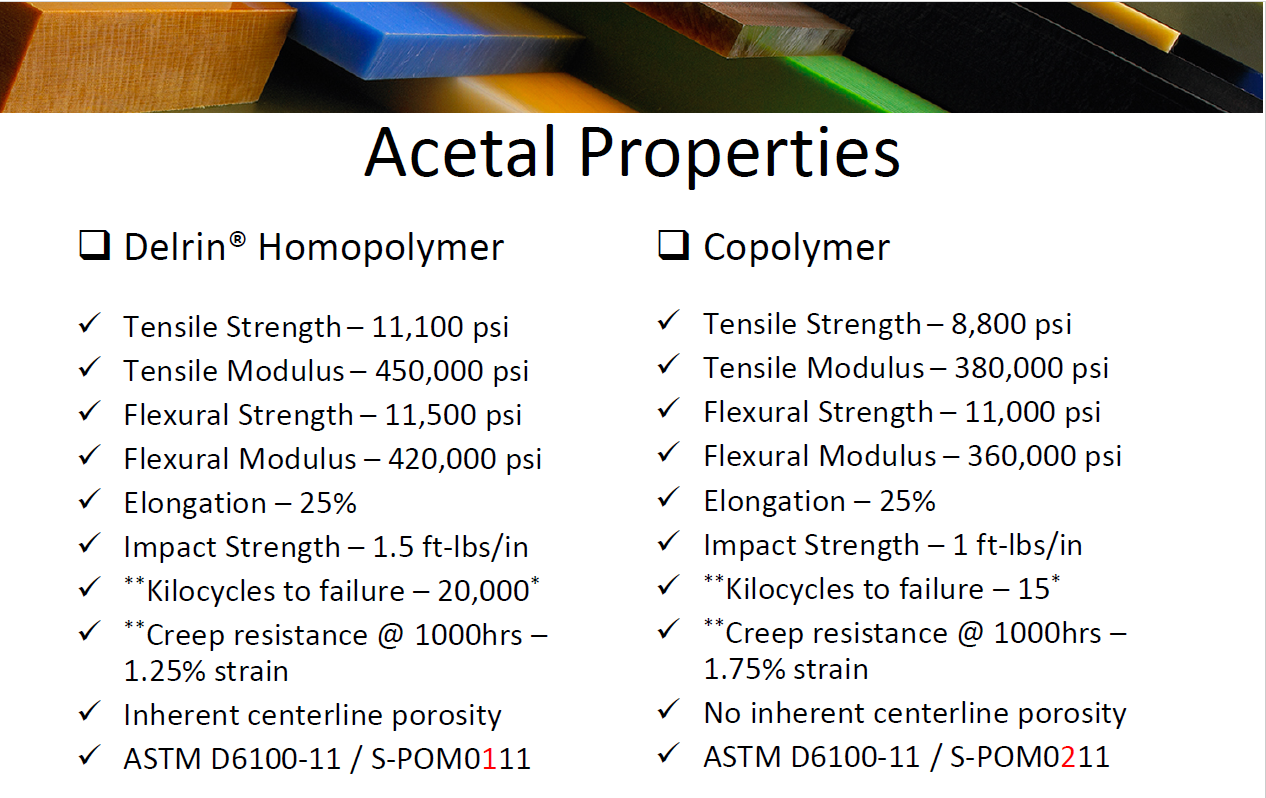

In most applications, Acetal Homopolymer and Acetal Copolymer can be interchanged however, there are a few key considerations. Generally speaking, Acetal Homopolymer provides:

- Superior physical properties

- Higher crystallinity

- Better fatigue endurance

- Better creep resistance

- Better impact resistance, especially at low temperatures

Acetal Homopolymer stock shapes inherently contain significantly more centerline porosity than Acetal Copolymer stock shapes. This is most prominently displayed in thick sheets and large diameter rods. In addition to aesthetic differences, a significant porosity line can compromise structural integrity, and present routes to leakage.

If you have questions about these materials, our team of experts are happy to assist you. Email sales@plasticsintl.com or call (952) 934-2303.